In today’s digital age, RFID cards have become invisible heroes in daily life—powering contactless payments, streamlining logistics tracking, securing building access, and enabling seamless asset management. Behind every small, thin RFID card lies a sophisticated production process that blends precision engineering, material science, and strict quality control. Let’s take a deep dive into the full journey of RFID card production, from the initial chip selection to the final inspection of finished products, and explore how each step shapes the performance and reliability of these essential smart devices.

Step 1: Chip Selection – The “Brain” of the RFID Card

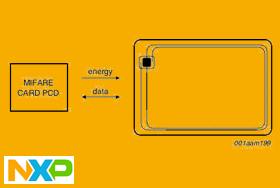

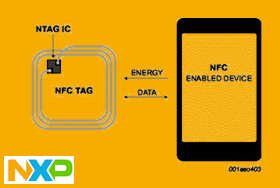

The chip is the core of an RFID card, responsible for storing data, receiving signals, and executing communication commands. Its selection directly determines the card’s functionality, reading distance, and application scenarios.

- Chip Type Matching: RFID chips are categorized by frequency, including Low Frequency (LF, 125kHz), High Frequency (HF, 13.56MHz), and Ultra-High Frequency (UHF, 860-960MHz). LF chips are ideal for short-range, low-speed applications like animal tracking; HF chips (e.g., ISO 14443-compliant) excel in payment cards and access control due to their stable data transmission within 10cm; UHF chips, with reading distances up to 10 meters, are perfect for logistics and inventory management where long-range scanning is needed.

- Performance Priorities: Manufacturers evaluate chips based on storage capacity (from 128 bytes to multiple kilobytes), anti-interference ability (resisting electromagnetic noise in industrial environments), and power consumption (critical for passive cards that rely on reader energy). For high-security scenarios like e-passports, chips with advanced encryption algorithms (e.g., AES) are non-negotiable.

- Supplier Reliability: Reputable chip suppliers (such as NXP, Texas Instruments) ensure consistent quality, reducing the risk of batch failures. Production teams often conduct pre-testing to verify chip compatibility with antennas and end-use systems.

Step 2: Material Selection – Balancing Durability and Functionality

The physical “body” of an RFID card depends on high-quality materials that protect internal components while meeting application-specific demands.

- Base Material Choices: PVC (Polyvinyl Chloride) is the most common due to its low cost, flexibility, and ease of printing—ideal for standard access cards and transit passes. PET (Polyethylene Terephthalate) offers better heat and chemical resistance, making it suitable for industrial or outdoor use. For eco-conscious clients, biodegradable materials or recycled PET are emerging as sustainable alternatives.

- Substrate Thickness: Typical RFID cards range from 0.76mm to 1.2mm in thickness. Thinner substrates (0.76mm) are preferred for sleek designs in payment cards, while thicker substrates (1.0mm+) provide extra durability for rugged environments like construction sites.

- Adhesive and Lamination Films: High-strength adhesives ensure the chip and antenna stay securely bonded to the substrate, while lamination films (e.g., matte or glossy finishes) enhance scratch resistance and print quality.

Step 3: Antenna Design & Fabrication – The “Communication Bridge”

For contactless RFID cards, the antenna is the unsung hero that transmits radio frequency signals between the card and the reader. A poorly designed antenna can lead to weak signals, short reading distances, or unstable communication.

- Frequency-Driven Design: Antennas are tailored to match the chip’s frequency. HF antennas are typically small, circular or rectangular coils (printed or etched) that resonate at 13.56MHz, ensuring efficient energy transfer in close proximity. UHF antennas, larger and often dipole-shaped, are optimized for long-range signal propagation, with designs accounting for impedance matching to minimize energy loss.

- Precision Manufacturing: Antennas are fabricated using techniques like copper etching (for high conductivity) or silver paste printing (cost-effective for mass production). Advanced manufacturers use automated laser etching to ensure coil uniformity, reducing signal variations between cards.

- Testing for Performance: Prototypes undergo rigorous testing in anechoic chambers to measure reading distance, signal strength, and interference resistance. Adjustments to antenna length, coil turns, or material thickness are made to optimize performance for the target application.

Step 4: Chip Bonding – Merging the “Brain” and “Bridge”

Once the chip and antenna are ready, they are bonded together in a process that requires micron-level precision. This step ensures the chip can receive energy from the antenna and transmit data seamlessly.

- Bonding Techniques: The most common methods are flip-chip bonding (where the chip is directly attached to the antenna’s contact pads using conductive adhesives) and wire bonding (thin gold or aluminum wires connect the chip to the antenna). Flip-chip bonding is preferred for high-volume production due to its speed and reliability.

- Environmental Controls: Bonding is performed in cleanrooms (Class 1000 or higher) to prevent dust or particles from interfering with the connection. Temperature and humidity are strictly regulated to ensure adhesives cure properly and wires bond securely.

- Post-Bonding Inspection: Automated optical inspection (AOI) systems check for bonding defects—such as misalignment, weak adhesion, or wire breaks—catching issues early to avoid performance failures later.

Step 5: Lamination & Card Formation – Shaping the Final Structure

Lamination transforms the fragile chip-antenna assembly into a robust, user-friendly card. This step involves layering the substrate, antenna, and protective films under controlled heat and pressure.

- Layer Alignment: Multiple layers (including printed overlays, core substrate, and adhesive sheets) are aligned with precision to ensure the chip and antenna remain centered, preventing warping or signal blockage.

- Lamination Parameters: Temperature (typically 120-150°C), pressure (5-15 bar), and time (20-40 minutes) are calibrated based on material type. PVC laminates require lower temperatures to avoid melting, while PET-based cards can withstand higher heat for stronger bonding.

- Edge Trimming: After lamination, the card is cut to standard sizes (e.g., CR80, 85.6×53.98mm) using die-cutting machines, ensuring clean edges and consistent dimensions.

Step 6: Personalization – Adding Brand Identity and Data

Personalization tailors the card to its end user, including visual customization and data encoding.

- Printing: High-resolution UV printing or thermal transfer printing adds logos, text, barcodes, or security features (e.g., holograms, microtext) to the card surface. For high-security applications, laser engraving creates permanent, tamper-proof markings.

- Data Encoding: Each card is programmed with unique information—such as user IDs, access permissions, or payment credentials—using specialized encoders. Encryption protocols (e.g., 3DES, RSA) are applied to protect sensitive data during and after encoding.

- Quality Checks for Personalization: Inspectors verify print clarity, color accuracy, and data integrity, ensuring the card meets both aesthetic and functional requirements.

Step 7: Finished Product Inspection – Ensuring Reliability

The final inspection is the last line of defense against defects, guaranteeing that every card performs as intended in real-world scenarios.

- Appearance Inspection: Automated vision systems check for scratches, bubbles, misprints, or warping. Cards with visual flaws are rejected to maintain brand quality.

- Performance Testing: RFID testers simulate real-world conditions to measure reading distance, signal stability, and data transmission speed. UHF cards undergo multi-tag reading tests to ensure they can be scanned alongside hundreds of other cards without interference.

- Environmental Validation: Samples are subjected to extreme conditions—high/low temperatures (-20°C to 60°C), humidity, and mechanical stress (bending, impact)—to verify durability in harsh environments.

- Compliance Certification: Cards for regulated industries (e.g., healthcare, finance) are tested against international standards (ISO 14443 for HF, ISO 18000-6 for UHF) to ensure they meet security and performance benchmarks.

Conclusion: Precision in Every Step, Trust in Every Card

From chip selection to final inspection, RFID card production is a symphony of precision, technology, and quality control. Each step—whether optimizing an antenna’s design, bonding a chip with micron accuracy, or testing for extreme durability—contributes to a card that is not just a tool, but a reliable partner in daily life.

For businesses seeking RFID solutions, understanding this process highlights the importance of choosing manufacturers that prioritize rigorous testing, material quality, and technological innovation. After all, a high-performance RFID card isn’t just built—it’s engineered, with care and precision in every detail.

In a world where connectivity and security are paramount, the journey of an RFID card from production line to pocket is a testament to the power of smart manufacturing. And with continuous advancements in materials, chips, and testing, the future of RFID cards promises even greater efficiency, durability, and versatility.

HUYI RFID Technology is an innovative IoT company deeply rooted in the IoT industry, driven by core RFID technology. We integrate product design, R&D, production, and sales into a complete industrial chain. Our product portfolio covers but is not limited to RFID cards, RFID wristbands, RFID tags, RFID labels, and RFID key fobs. We also provide customized solutions such as RFID animal traceability tags, washable and wear-resistant rfid laundry tags, and rfid hotel key cards, alongside high-performance RFID readers and supporting peripherals—from lanyards and card holders to custom printed cards, paper printed materials, and packaging products—fulfilling customers’ one-stop procurement needs comprehensively.